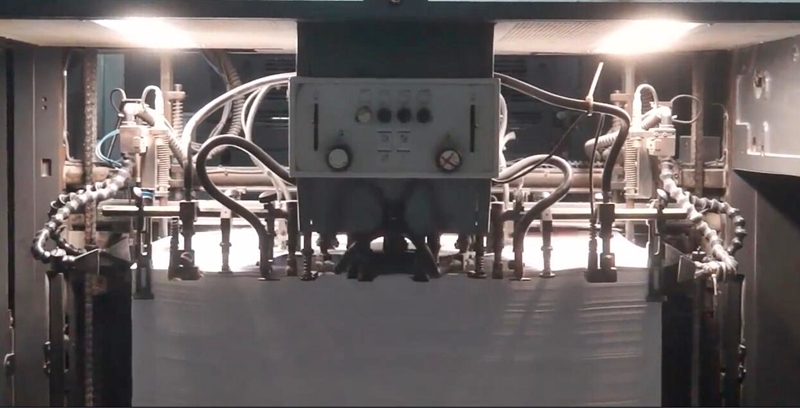

For a paper box factory, it is good to know some ways of saving cost for both printing and handcraft process. Today we will talk about the factors of affecting printing resistance.

Printing resistance have a printing plate is directly related to the economic benefits of paper packaging production, and it is also an important condition to reduce production cost, improve production and ensure printing quality. Gravure ink and environment on the plate cylinder seal force resistance should be the major influencing factors: ink viscosity and drying speed, sand, dust and other impurities, ink, aggressive, and chemical factors of reason.

In order to remove the excess ink from the surface of the plate cylinder, the scraper must penetrate the ink ink ink film, so when the ink viscosity is large, the need for a larger circle of scraper pressure. Therefore, to minimize the ink viscosity, in order to reduce the pressure of the scraper.

In addition, excessive ink drying, plate cylinder and scraper friction between the relatively increased, on the plate cylinder life a certain impact. With wet through a big environment, resulting in ink dispersivity, plate cylinder shave not easily, therefore will have to increase the pressure of scraper, also corresponding increase the scraper of friction plate cylinder.

If there are hard particles in the ink, when scraping the ink plate cylinder is easily cut by hard particles, light impact printing quality, heavy caused plate cylinder scrap. Other impurities on the surface of the substrates easily also mixed in ink, after a long time accumulation is overmuch, also easy to damage to the plate cylinder, so try to keep the substrates and ink clean length is often necessary. In order to remove foreign matter, the ink in the ink tank can be filtered on schedule or in the ink cycle system inserted into the metal screen for continuous filtering. No matter the dust in the environment into the ink is still adsorbed on the imprint lithography drum will directly damage the scraper and the plate.

Some inks such as black ink to the plate cylinder have a certain erosion, so after the use of timely cleaning.

Joined in the process of ink fruit of a certain amount of surfactant, if ink or the activity of the plate cylinder is too high, active substances in the process of printing will be more firmly stick on the plate cylinder, scraper is difficult to fully scrape, thus have to progress squeegee pressure, will affect the life of the plate cylinder. At this time, the plate cylinder can be clean, clear the plate cylinder has been attached to the active substances, in the ink to add a special surface active retardant, will achieve a significant effect. If the surface-active retardant is added before printing, it can be prevented.

We are custom paper box factory, we are focus on custom manufacturing of exquisite manual paper gift boxes. Our website is: https://www.yisonprinting.com

If you want to learn more about us, please contact us, we will give the best service for you.

1.Ink viscosity and drying rate

2.Effects of impurities such as hard sand and dust

3.The erosion of ink

4.Chemical factors